2017

December 30, 2017 Leave a comment

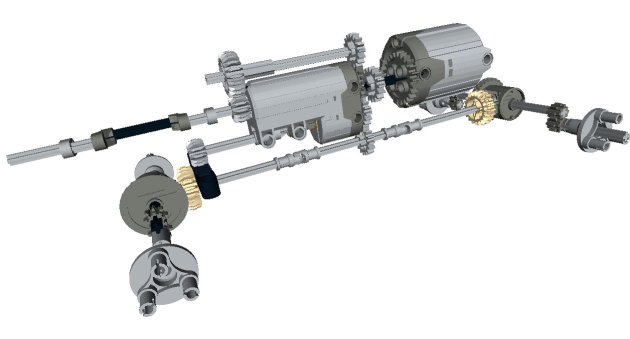

As the calendar reminds us another year comes to a close, it is time to reflect on what happened in Thirdwiggville. As I look back over the last couple of years, it is clear that little thirdwiggs are affecting what and how I am building. I am pleased with the builds I am able to accomplish amidst all the other life responsibilities. Let us look back at what happened this year. As a recap, here are the 2017 builds: Unimog U90, Mack Magma, Mini Mack Cabover, BMW R Nine E, Forest Fire Truck, Coast Guard Helicopter, Mercedes Benz Arocs, and The Toaster.

- Unimog U90

- Mini Mack Cabover

- Mack Magma

- BMW R nine E

- Forest Fire Truck

- Coast Guard Helicopter

- Mercedes Benz Arocs

- The Toaster

Some reflections on 2017:

First, I completed some of my goals from last year.

- A Model Team airplane: Not completed

- Another airplane: Not completed, but it was because I did a helicopter instead.

- A motorcycle: Completed

- A small truck (dump): Completed

- A big truck (PF, rolloff): Not completed

- A pickup truck (PF): Not completed

- A Large GT car: Not completed

- Something pneumatic: Not completed, but close to done.

- Not listed as an official goal, but I did keep to one bricklink.com order per month.

Second, the U90 and Coast Guard Helicopter are two builds I very much enjoyed this year. They are both still build, and adorn my shelf at work.

This tells me my life maybe needs fewer goals. I am still finding time to build, but being a little more fluid in what I am working on may be a good change. In 2018 I will watch which direction my building goes, and see what happens.

With this in mind, here are a few goals for next year.

- Something pneumatic.

- A tractor

- Something big and PF

- A Car

- A model team build

On to 2018!