LEGO 42126 SVT8/10

April 11, 2022 1 Comment

I loved LEGO set 8081 because it gave me a lot of modification ideas, and LEGO 42126 is similar.

Instructions may be found at Rebrickable for the SVT10 and the SVT8.

In addition to the 4×4 version of 42126, I was immediately interested to making a sport version of the pickup. The sport pickup is one of those silly American contributions to the automotive landscape, so naturally I had to turn the most American of vehicles, the F-150, into a sport truck.

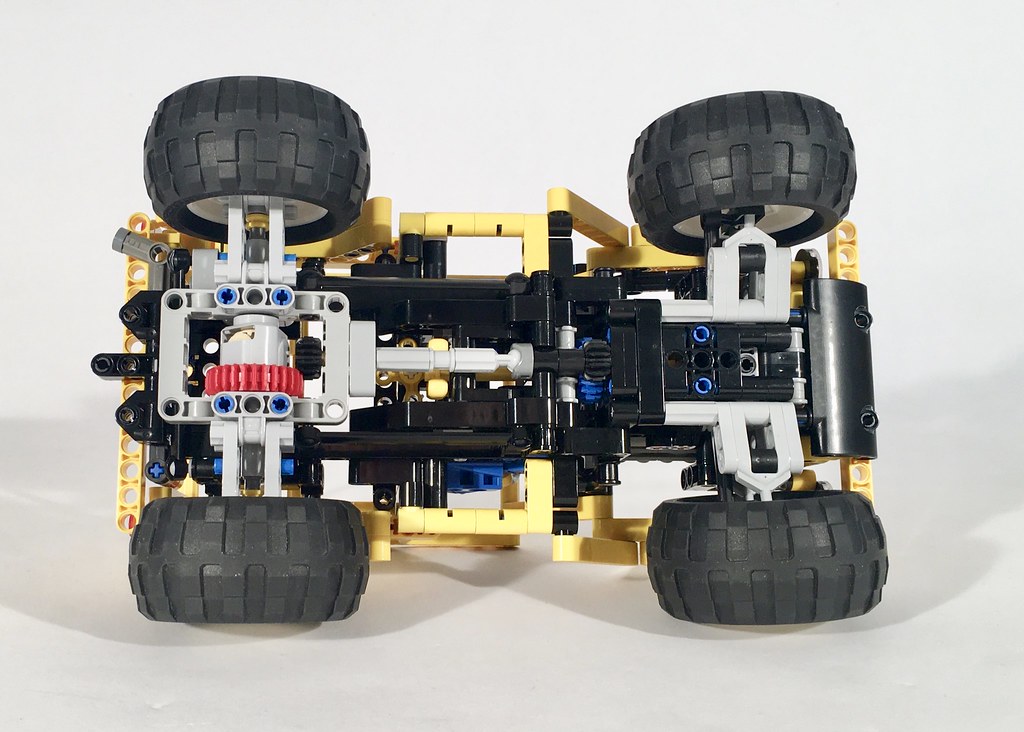

First, I had to figure out how to set the ride height. I decided on the wheels for the truck right away, so it was clear the truck had to come down a little bit. It was clear this would be a significant modification. Since I was already changing the whole frame for the ride height drop, I decided early that i would change the rear suspension to an independent design.

Second, I had to decide on what engine I would use. It was clear at this point, I would have a two door and four door version so I decided a V8 for one, and a V10 for the other. 42126 has a lot of space under the hood, so both would fit without a lot of changes. I added a chain driven supercharger for the V8 to give it a little different look.

Finally, I wanted to keep the bodywork similar to 42126, but with a sporty look. I designed a new front bumper that is lower, and looks less rugged. I removed the side steps from 42126, and replaced with some simple panels. A new hood was also designed.

Video for the SVT10.

Video for the SVT8.

Functionally, the truck worked better than the Raptor. The suspension worked very well, thought the rear ride height was a little high. The steering worked well, and the front wheels tracked better than on 42126. I liked the look a little better as well, as the wheels and tires make 42126 look out of scale with itself. I pleased with how the updates turned out, so we’ll see if I come up with another MOD to do at some point.

Until then, happy building!