LEGO 42168 Backhoe

February 24, 2024 Leave a comment

I have been bitten by the Alternative Build bug.

Instructions may be found at Rebrickable.com.

A couple of years ago I decided that it was time to learn how to make an alternative build. I recognize how more people are looking for ideas to turn a set they have purchased into another build. Well, since I enjoy building other design, I am happy to share these with other people. Plus I like the challenge an alternative build poses: a limited amount of parts to make a MOC. LEGO set 42168 is a cute little tractor with some fun features, but what I really like about it is the green. It is a small, accessible set, and has some fun parts, that can be used to build something else.

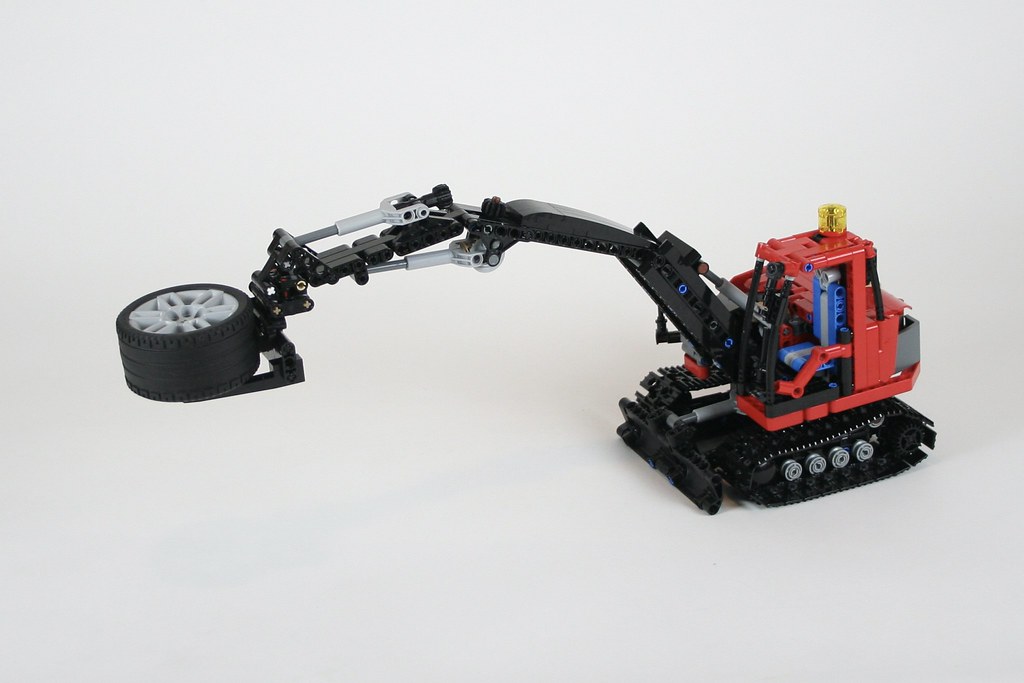

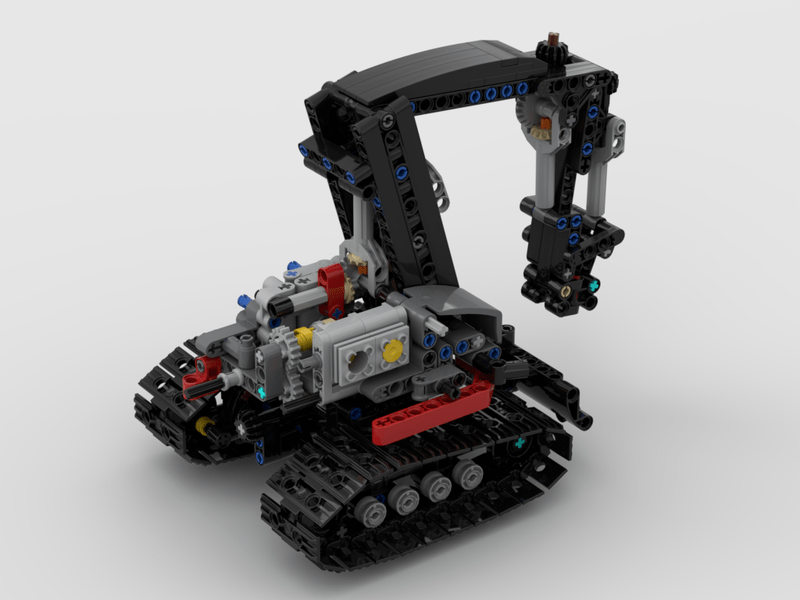

Since the set comes with two different size wheels, I decided a little backhoe would be a good idea. Plus, with the amount of yellow parts, I could use them on the rear arm and front loader. As I do with all of my builds, I started with draft including all the functions I wanted the final build to have. Quickly I had a draft with working steering and a little fake I3 engine. The I worked on how the front loader would work, and the rear arm mechanism.

As I worked on the rear arm, I was not pleased with any of the bucket designs I came up with, so I instead designed a couple of attachments that fit the tractor a little better. A little drill and a claw are included in the build. The rear arm moves in a number of ways, and the tractor also has two stabilizing arms to keep the tractor from tipping over. I used a similar approach for the front loader as well. A bucket option is included, but I find the design a little clunky looking. It includes a set of forks as well which I like a little better. A little pallet to load is included. Both the lift and tilt are manually operated, and the lift includes a lockout level so the arm may hold up a heavy load.

I like to think I am getting better at alternative builds, but I do not think this is my best one. I find the design a little rough, even though the functions work well. I hope that some other builders find some enjoyment in this design, and I’ll keep working on more ideas to make available in the future.

Until then, happy building.