Power Functions 4×4 8081

May 18, 2012 9 Comments

For most LEGO enthusists, when they purchased the set 8081, they quickly modified the set with a Power Functions drivetrain. It makes sense. LEGO models are a little more exciting when they are motorized. But I guess I went a little backwards. I wanted to do the fun stuff first, and make the most complicated and compact drivetrain I could make. I posted the instructions here, and they can also be viewed on Rebrickable.com.

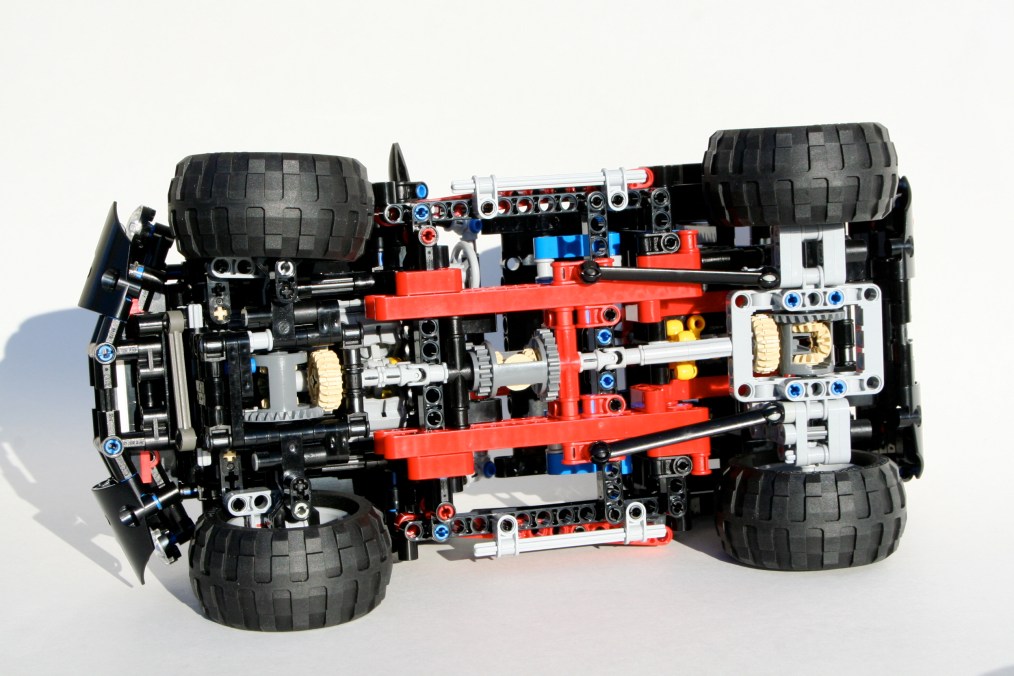

But the comments kept coming from people who wanted to see my model motorized. So I thought it might be a fun addition. I added a two PF M motors, a 8878 Battary Box, and an IR receiver. I tried to keep the modifications simple, so I could easily add the motors to the MOD, and take the system out if I wanted to. The drive motor was placed on a simple mount that connected to the frame. The power was fed thought a 8z gear to a 24z gear which then connected directly to the V8 driveshaft. The driveline was unchanged from the V8 down. The steering motor was mounted laterally in front of the rear seats. A 20z double bevel gear drove a 16z gear, then a worm gear moved the final 8z gear which was mounted on the existing HOG steering axle. I removed the passanger seat which is where I placed the battary box, and created a simple mount for the IR receiver. The added weight required a new shock absorber, so I added that as well.

The model worked alright. The drivetrain did well to handle the new power, and I could easily control the Crusier. The steering motor was a little too powerful for the upside down facing steering rack. It skipped a little under load, which was a problem over rougher terrain. The drive motor was a little taxed, so a PF XL would have done a little better. I guess I could add that, but I am ready to move on to my next model. Stay tuned.

The full gallery may be found here.