Unimog U4000/5000

April 15, 2024 Leave a comment

Time for another Thirdwigg Unimog!

Instructions are available at Rebrickable.com.

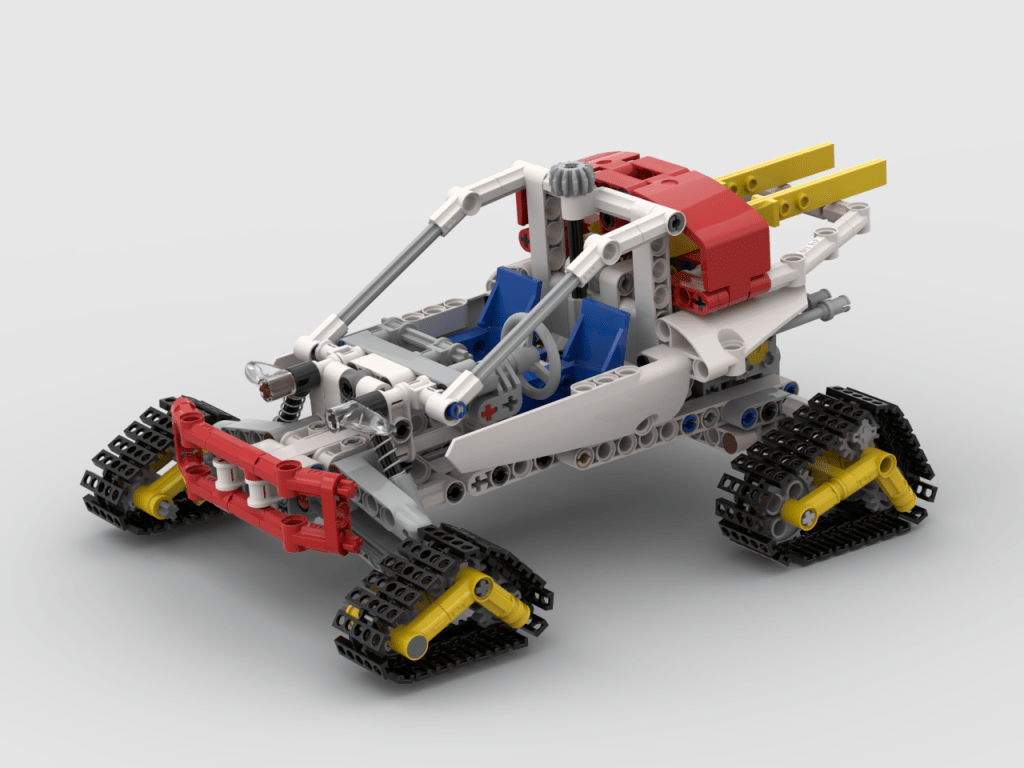

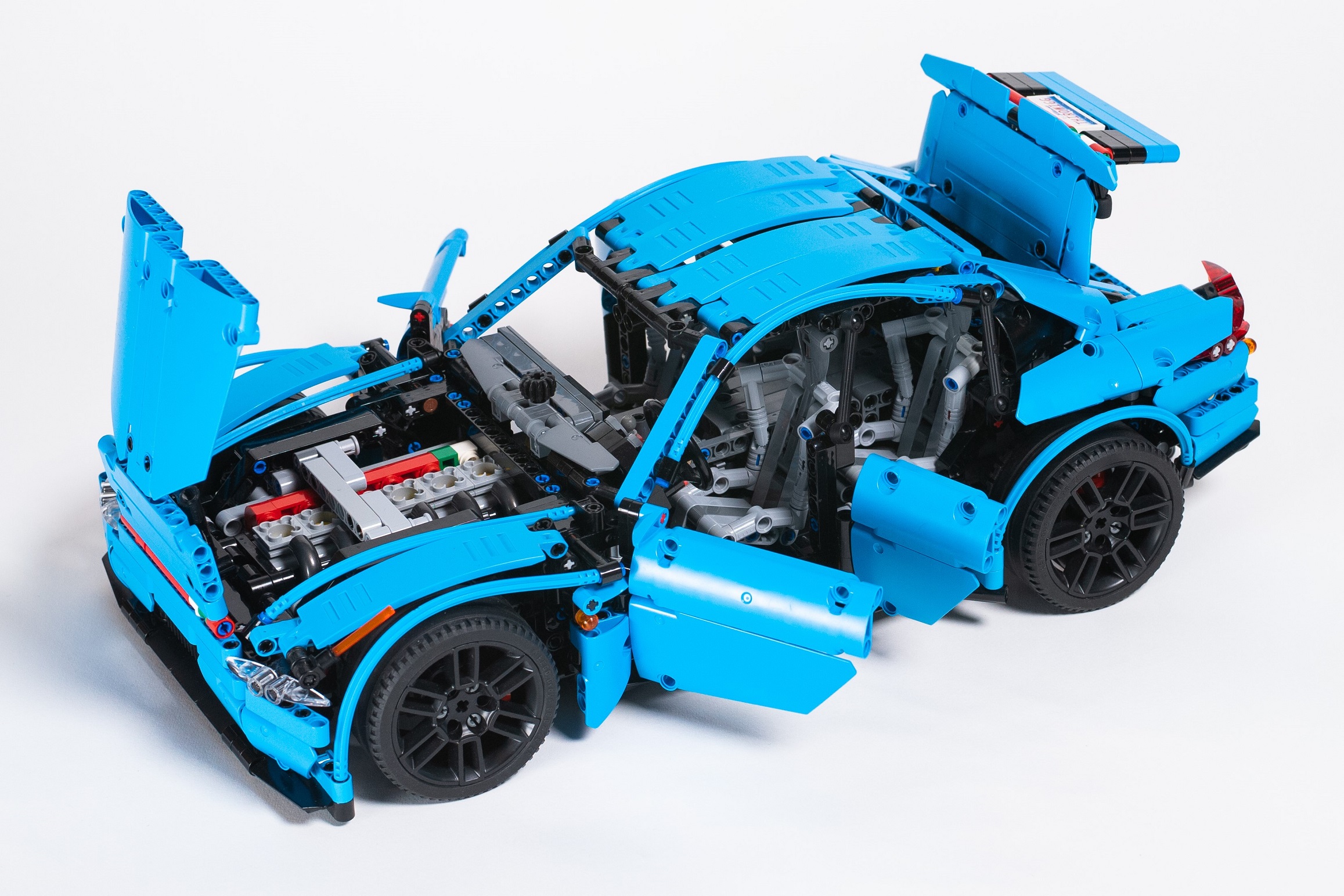

I am now averaging about one Unimog a year now, so it was about time for me to make another one. The 1:21 scale truck is now fairly common, for good reason: it’s a playful size, it does not take too much space or too many parts, and yet gives plenty of space for functions. The popularity of the U423 led me to try a U4000/5000 version.

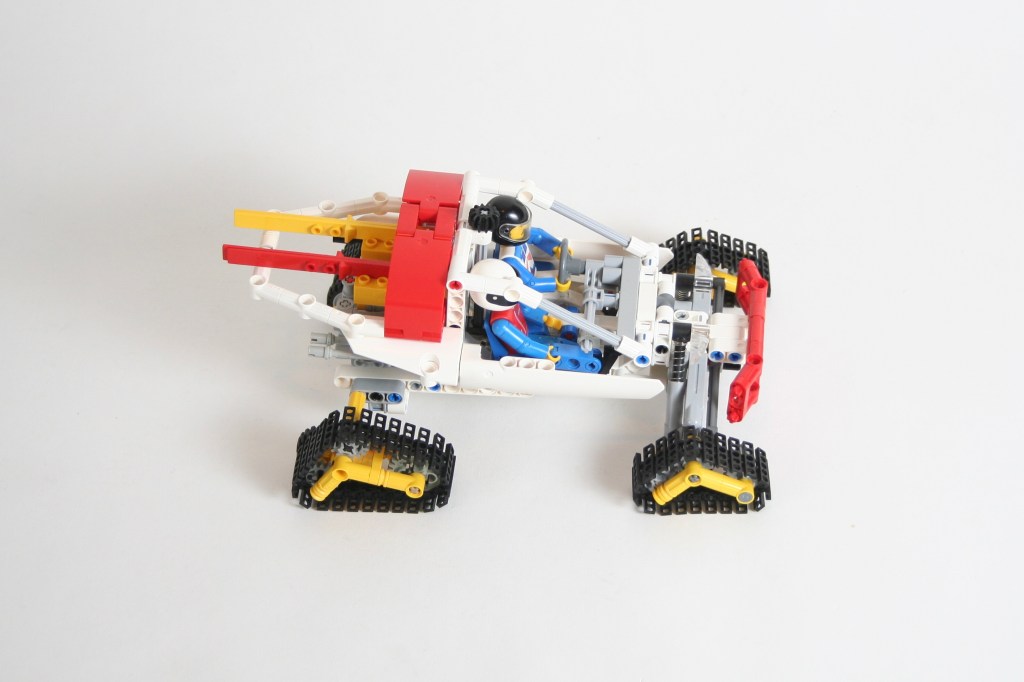

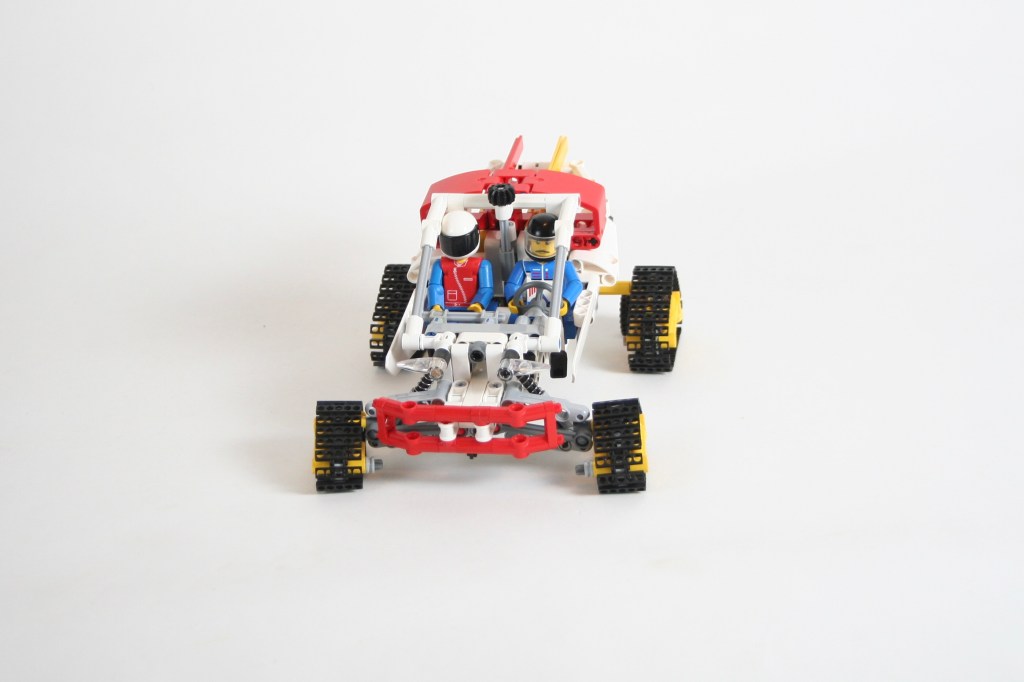

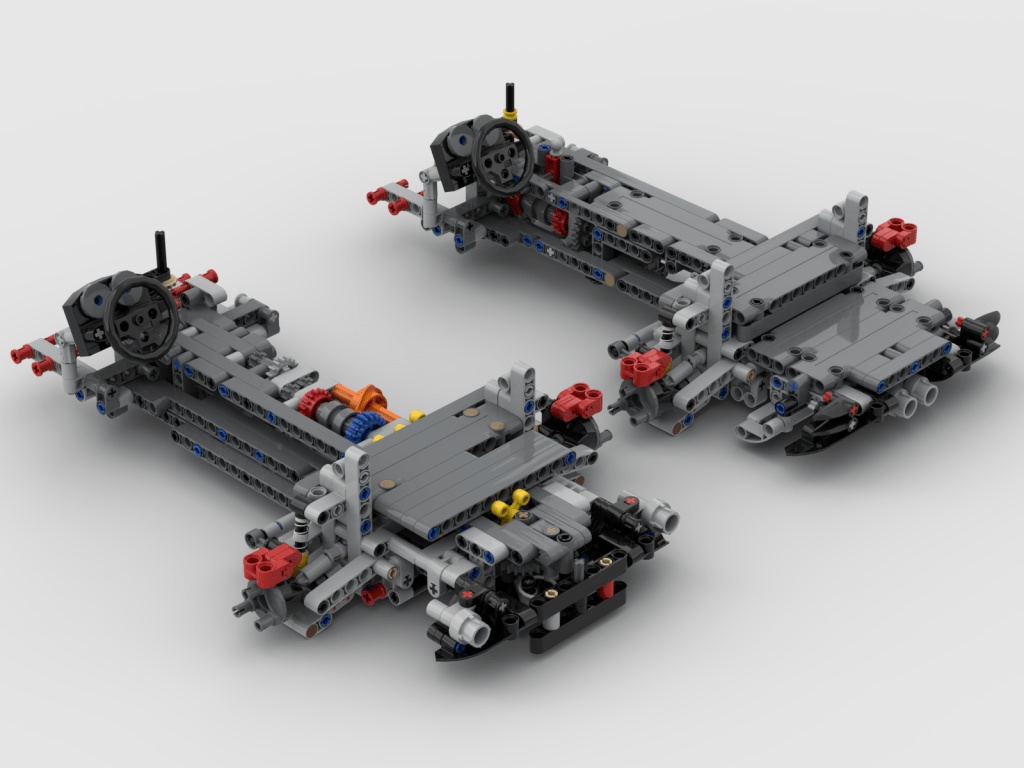

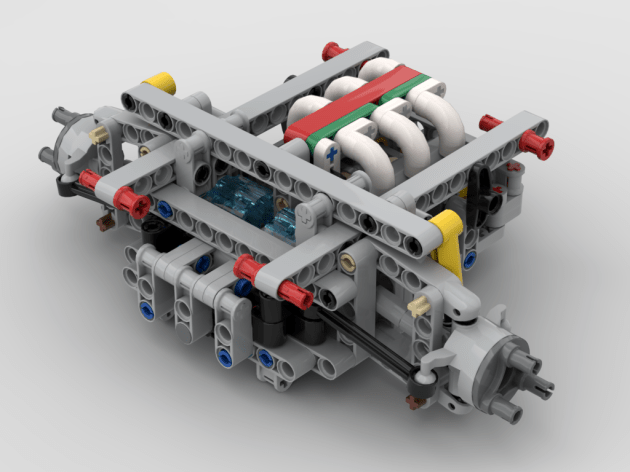

As I started designing, I wanted to have the standard functions: steering, a drivetrain, an engine. But once I placed these functions, I was left with a lot of space, and the truck was missing something to set it apart from all the other Unimogs. I added a simple two speed transmission, but I still wanted another function. After some looking at a number of photos of the U5000, I started noticing a common feature: a winch.

With a little bit of work, I was able to add both a front and rear winch. The front is mounted to the right of the engine with a HOG on top of the cabin next to the steering HOG. The front winch has a lock, which can be released by moving the step on the right of the truck. The rear winch is controlled by a HOG on the right of the truck, with a lock under the fuel tank.

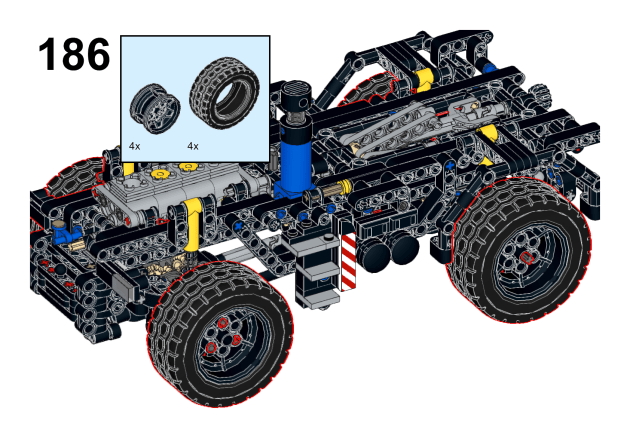

In addition, I wanted some options for bodies, so I created two chassis lengths. The short wheelbase (U4000) has a 19 stud wheelbase, and the long wheelbase (U5000) has a 24 stud wheelbase. Both are similar in design, but have different bed lengths. The U5000 version also allows for both a standard, and four door cab. For the long wheelbase version, I built a fire truck box, and a long bed. For the short wheelbase version, I built a bed and a little camper. The camper features a bathroom, little kitchen, and a table to converts to a bed. Also, plenty of storage compartments are both inside and on the outside of the camper. Finally, a little tipper trailer is available. I built it to match the Dark Bluish Grey U4000, but it can be made in many colors.

I have created instructions for each of these versions, and each can be found at Rebrickable.com: U4000 SWB Truck, U5000 Fire Truck, U5000 LWB Truck, Trailer, Camper.

Just like the U423, I was very happy with how these trucks turned out. The Dark Bluish Grey version is my favorite. The trucks work well, and have all the functions a 1:21 scale truck should. I love all the functions; playing with the winch is great fun! The hood is a little too fragile for my liking, but it looks just like it should. Also, it was a great reason to finally build a camper, and this won’t be the last time. But first, we may need to do another Unimog in 2024. Stay tuned….

Happy Building…